![]() info@cotton-rosebd.com

info@cotton-rosebd.com

Cotton Rose puts a lot of effort & emphasis on process institution & execution for a quality product. Therefore, the planned and systematic activities are implemented in the quality system so that the quality requirements are fulfilled. Our Quality Assurance activities also include quality management for Raw materials, Fabric & Colour composition, Products & components, and the services related to Production management through Inspection processes. Our experienced quality assurance team enforced the quality process at all phases of production and followed-up constantly to the factory for implementation.

Through a strict regimen of quality checks & controls, we maintain a consistency in the quality of raw materials procured, in the quality of our manufacturing work, in packaging, in Shipment & Service etcetera.

Through a strict regimen of quality checks & controls, we maintain a consistency in the quality of raw materials procured, in the quality of our manufacturing work, in packaging, in Shipment & Service etcetera.

Risks are reduced by inspecting accessories, performing Color Matching checks, Fabric Inspection, Lab dip testing, Daily Cutting checking, Wash testing, Knitting & Flannel Inspection, Measurement Spec checking.

First, finished products are checked against the buyer’s specifications and a prototype sample. Deviations are identified and corrected.

Inspection during production is carried out to check and verify that the initial discrepancies have been rectified and to ensure the best quality standard of production runs.

The detailed physical inspection of the samples selected individually is based on the specification of the buyers, and it covers criteria such as design/ style, shrinkage, accessories, appearance, markings, colors, labelling, material, assortments, craftsmanship, measurements and packing.

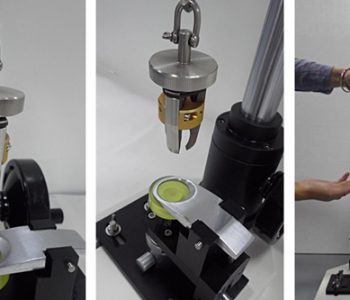

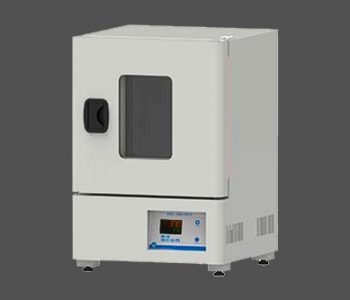

The team follows the adequately laid out process and customized formats for each process by taking approvals from the buyer at all required milestones. The team ensures that all the procedures, systems and methods are well institutionalized among the groups of vendor partners and followed to meet buyer’s expectations. Cotton Rose has all the Modern equipment to ensure the quality as per buyer requirement. We have Light Box, barcode reader matching, Gsm matching, Dummy etcetera. So, we can check everything before sending to the final buyer. We also aware about the present European law and maintain it.